STMicroelectronics in

Crolles, France

Discover our site

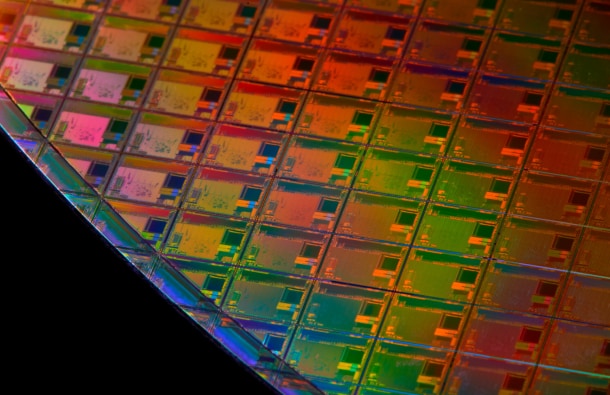

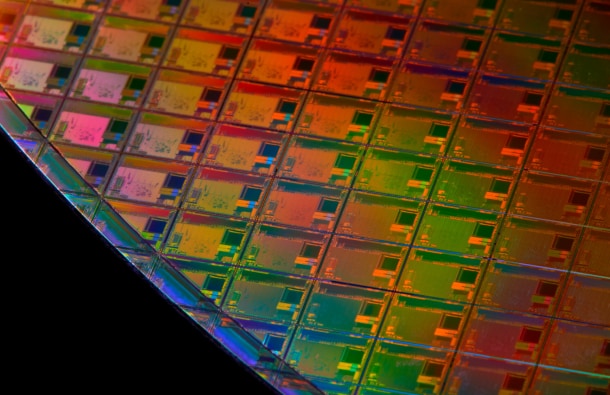

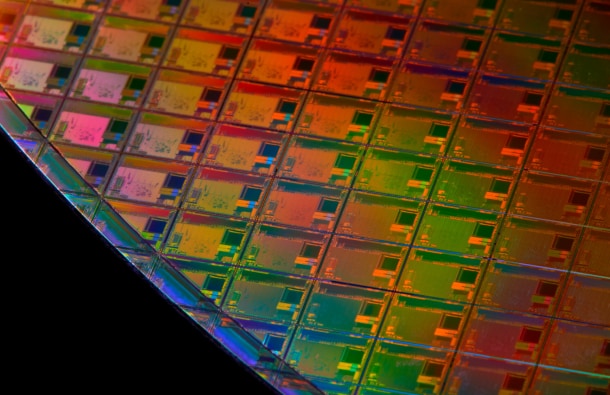

ST’s Crolles site houses design, R&D and production activities for the development and manufacturing of chips in digital technologies on 200 mm and 300 mm silicon wafers. With more than 5,000 employees in Crolles and over 2,000 in ST’s R&D center in Grenoble, ST is the biggest private employer in the region.

Advancing sustainable IC design

Our Crolles site serves as an R&D center dedicated to advancing IC technology design. Our mission is to improve the technical performance and environmental sustainability of our products and manufacturing processes. Collaborating with colleagues from Grenoble, Rousset, and Noida, our R&D teams develop programs to reduce the electrical consumption of integrated circuits and their peripherals.

Our people

Developing managerial culture

In 2023, we launched the "CoDev Managers" initiative to develop managers and foster the managerial culture at our Crolles site. Using the co-development methodology, this initiative fosters a community for exchanging working methods, addressing challenges, and solving problems.

With over 30 workshops in 2023 and 2024, it shows our commitment to continuous improvement for our employees.

Maintenance Academy is nurturing excellence

The Maintenance Academy is a 3-week training program for all newcomers in maintenance, featuring attractive modules. Covering essential skills and best practices, it uses modern approaches like “learning by doing” and “giving meaning.” It also aims to develop a maintenance community by empowering experts as internal trainers and improving our attractiveness.

Your benefits at ST in Crolles

When people contribute, perform and get results, we feel they should be rewarded.

Total reward approach

Global mobility

Health and wellness plans

Work-life balance

Our actions towards sustainability

A sustainable culture beneficial for people, the environment, the economy, and society.

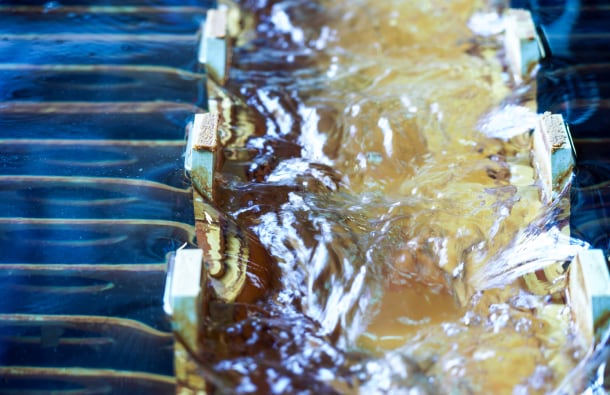

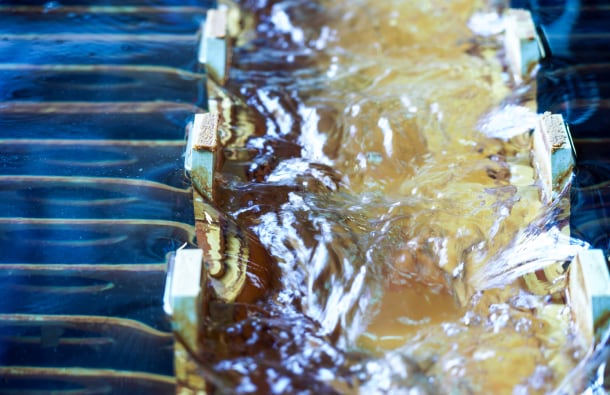

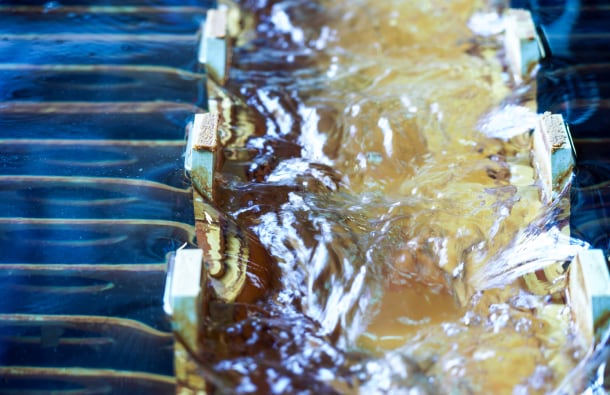

Innovation in water recycling

In 2024, we launched a pilot water recycling line at our Crolles site. This new installation recycles wastewater from the treatment plant and reuses it as ultrapure water in the production circuits. The pilot line is one of the first in the microelectronics industry in Europe. It is now qualified and will recycle and reinject about 40 cubic meters of water per hour.

Energy efficiency: a daily focus

Since 2013, ST's Crolles site has been ISO50001 certified. It is committed to continuously improving its energy consumption through a number of projects, such as the installation of free cooling systems, heat recovery chillers, and more energy-efficient equipment. The site has reduced its electrical energy consumption per wafer produced by 43% and its gas consumption by 62% since 2016.