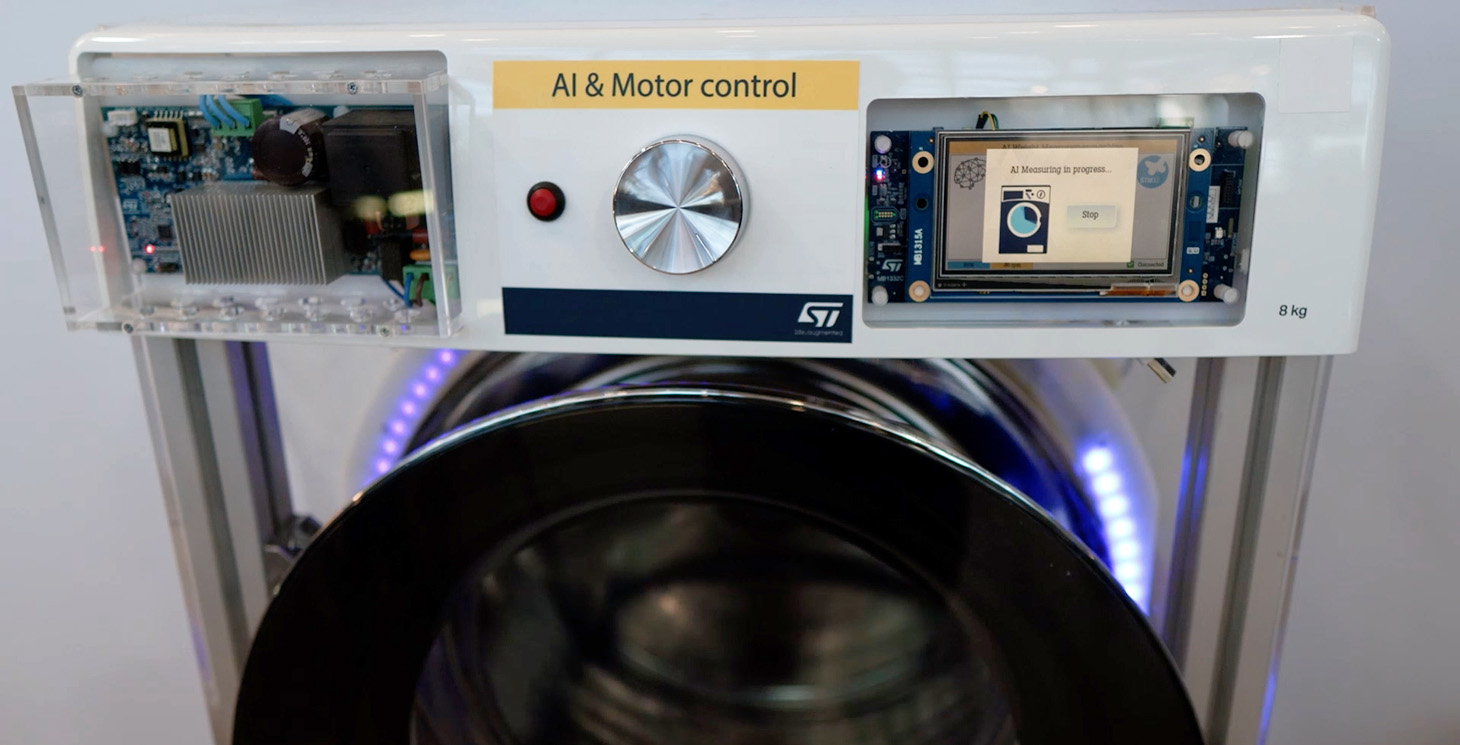

Accurately measure the weight of clothes inside a washing machine

Using AI to make your home appliances “smarter” and more energy efficient for a sustainable future.

This is only one example of what you can achieve using edge AI and NanoEdge AI Studio. This approach can easily be adapted to many other appliances or industrial machines.

Approach

- The current signals were measured directly from the motor control loop.

- Magnets were used to simulate different weight conditions.

- We used the Extrapolation algorithm provided by NanoEdge AI Studio to quickly build a regression machine learning model that accurately measures the weight of clothes inside the drum. The maximum estimation error reached was 100 g, which is three times better than the state-of-the-art solution on the market.

- Then, we ported the machine learning library to the same microcontroller as the motor control algorithm. NanoEdge AI Studio optimized the library so it fits in the MCU's internal memory.

Additional sensors and network connectivity are no longer needed since the processing is done at the very deep edge, in the motor of the machine itself. Processing the signal directly on the MCU increases security, safety, energy, and cost since only meaningful data is output and processed.

Sensor

Data

Data format Time series

Results

99.96% accuracy, 10.6 Kbytes of RAM, 9.5 Kbytes of Flash memory

Resources

Model created with NanoEdge AI Studio

A free AutoML software for adding AI to embedded projects, guiding users step by step to easily find the optimal AI model for their requirements.

Compatible with Any STM32 MCU

The STM32 family of 32-bit microcontrollers based on the Arm Cortex®-M processor is designed to offer new degrees of freedom to MCU users. It offers products combining very high performance, real-time capabilities, digital signal processing, low-power / low-voltage operation, and connectivity, while maintaining full integration and ease of development.