STMicroelectronics automotive thyristors offer 1200 V blocking capability at 150°C junction temperature and are fully qualified according to AEC-Q101 specifications. The 1200 V SCRs target OBC and BMS applications requiring high voltage capability and high temperature robustness.

Ranging from 30 to 60 A, ST SCRs for electric vehicles (EV) are designed for 2 to 22 kW OBCs (on-board chargers) bridge or bridgeless topologies in EV and BMS (battery management system) applications. They're particularly well suited for power factor correction. The optimized surge current capability and high turn-on performance also make our automotive thyristors fit for belt starter generators and capacitor discharge circuits.

Product types and portfolio

Automotive SCRs for OBC applications

On-board charging is a critical aspect of electric vehicle design and performance, as well as compliance with stringent automotive regulations. Traditionally, designers use a negative temperature coefficient resistor (NTC) and a bypass relay to limit the peak current at startup when connecting to the grid.

A semiconductor controlled rectifier (SCR) can replace electromechanical relays and NTCs. In addition to providing a smaller footprint and thinner design, SCRs enable improved inrush current control, faster charging times, and greater robustness to harsh automotive conditions (heat, vibrations, etc.).

Our innovative automotive-grade ACEPACK SMIT and HU3PAK surface-mount (SMD) packages with top-side cooling are designed to ensure higher power density and improved thermal management for very efficient and more compact systems.

All products are AEC-Q101-qualified.

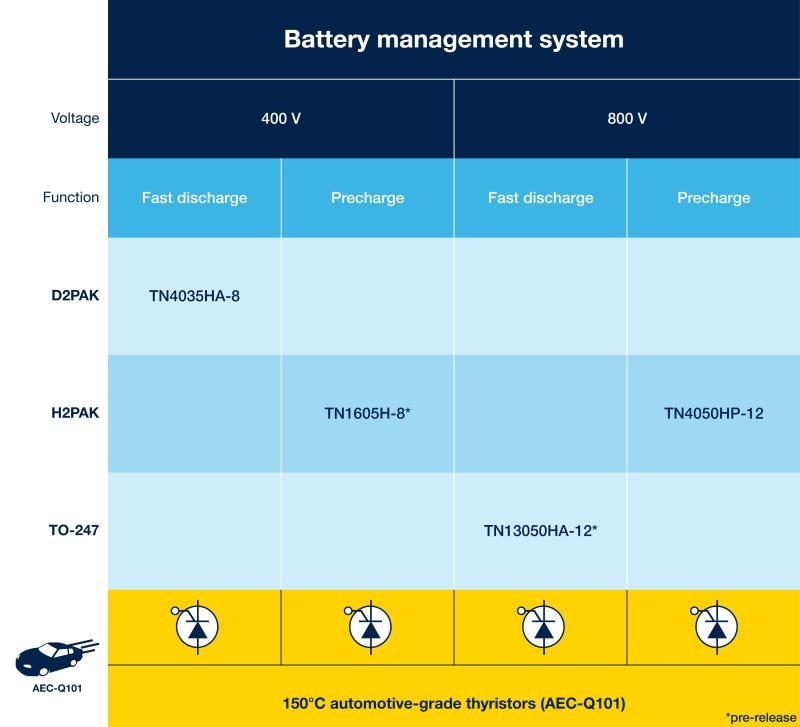

Automotive SCRs for BMS applications

Electric vehicles are trending from 400 V battery power sources to 800 V architectures that allow faster charging due to lower currents and heat in the charging cables, which also leads to lighter wiring harnesses.

Regardless of the battery voltage, power distribution units (PDU) are required to deliver power to all the critical vehicle systems and protect electronic components and vehicle occupants. In addition to a precharge circuit between the battery and the high-voltage bus to limit the inrush current when starting the vehicle, the PDU must include an emergency disconnect switch for the battery and a discharge circuit for the HVDC bus in the event of an accident.

Semiconductor controlled rectifiers (SCR) replace electromechanical relays and pyrofuse switches in power distribution units for electric vehicles. We offer 800 V SCR (thyristors) for 400 V lithium-ion battery packs as well as 1200 V SCRs for precharge and discharge solutions in 800 V architectures.

Our automotive-grade thyristors offer superior performance in peak voltage robustness and surge and inrush current handling at higher temperatures than traditional electromechanical relays or pyrofuse switches.

What are automotive SCRs used for?

- SCRs are primarily used for:

- OBC applications

- Substituting electromechanical relays and NTCs.

- Inrush current function

- BMS applications

- Precharge and discharge solutions up to 800 V

Benefits

- Improved inrush current control

- Higher power density and improved thermal management

- Superior peak voltage robustness and surge current handling at higher temperatures than traditional electromechanical relays or pyrofuse switches