Reach full torque at zero speed without sensors

Discover the software algorithms for STM32G4 microcontrollers

Enabling sensorless motor control in brushless DC and permanent magnet synchronous motors

In PMSM/BLDC motors running in FOC (field oriented control) mode, sensors determine the position of the rotor to control the motor properly. Dedicated algorithms, called observer algorithms, can take over from the sensors to allow the control of the motor in a so-called sensor-less mode. These observer algorithms work well at a high speed but are not efficient when the motor is running at a low or very low speed.

The STM32 ZeST (zero speed full torque) combined with the high-sensitivity observer (HSO) algorithm can control any type of BLDC or PMSM motor in sensor-less mode from zero to high speed. The STM32 ZeST and HSO are two software algorithms, thereby removing the need for additional sensors to control the motor.

The STM32 ZeST algorithm is currently available for selected customers only. The HSO algorithm is available in the new release of the motor control software development kit (SDK) (version 6.2)

What the STM32 ZeST and HSO algorithms offer

Evaluate the performance of the STM32 ZeST and HSO algorithms

Supporting hardware is available to evaluate the performance of the STM32 ZeST and HSO algorithms and accelerate the start of development.

These include the B-G473E-ZEST1S control board, which generates PWM signals for the power board, the STEVAL-LVLP01. This power board drives low-power/low-voltage motors like the one available in the B-MOTOR-PMSMA1 kit.

The control board connects to the power board using the new embedded motor-control connector V2.

Running in standalone, without the STM32 ZeST, the HSO algorithm brings the following benefits:

- When the control is not yet activated but the motor is spinning due to external action, the estimation of the rotor speed and position during the observation phase enables:

- Higher torque performance compared to legacy sensor-less solutions

- Improved end-user experience at startup (no break for back-EMF reading)

- Energy saving (lower peak current)

- High performance even at very low speed

- Easy to configure thanks to user-friendly interface

- Seamless transition between STM32 ZeST and HSO

- Field oriented control (FOC) and 6-steps supported from the motor control workbench (MCWB)

- More autonomy for developers to use and configure their own boards and features with the workbench

- Comprehensive graphical configuration thanks to the motor control workbench

- Most of the STM32 series supported

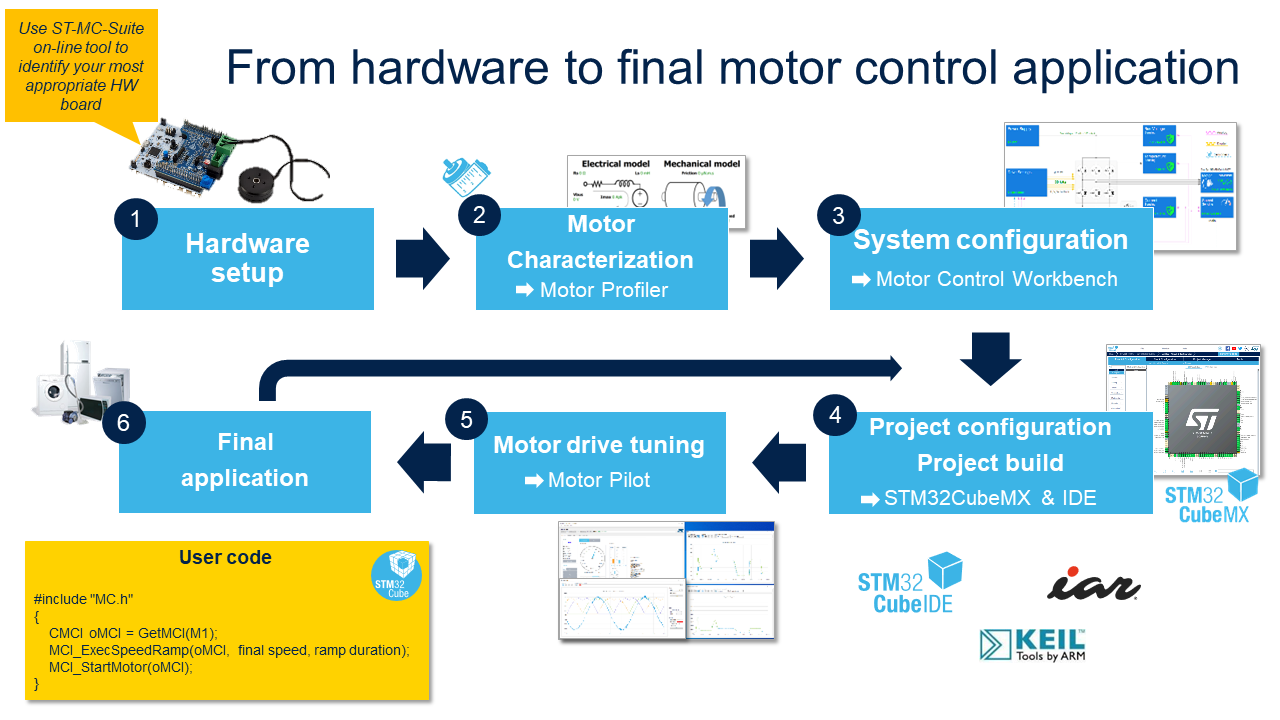

Design your motor control applications following this workflow in the motor control software development kits