Product overview

Description

The power liftgate system installed in commercial cars requires a foot movement, which is not always successful in opening the trunk. This limit is due to the type of sensor used, to its position under the car bumper, and to the required ‘kick’ gesture. Moreover, the sensor used has no alternative redundant system (excluding an internal fail-safe button) to open the trunk if it is not working because covered with mud or the street is flooded.

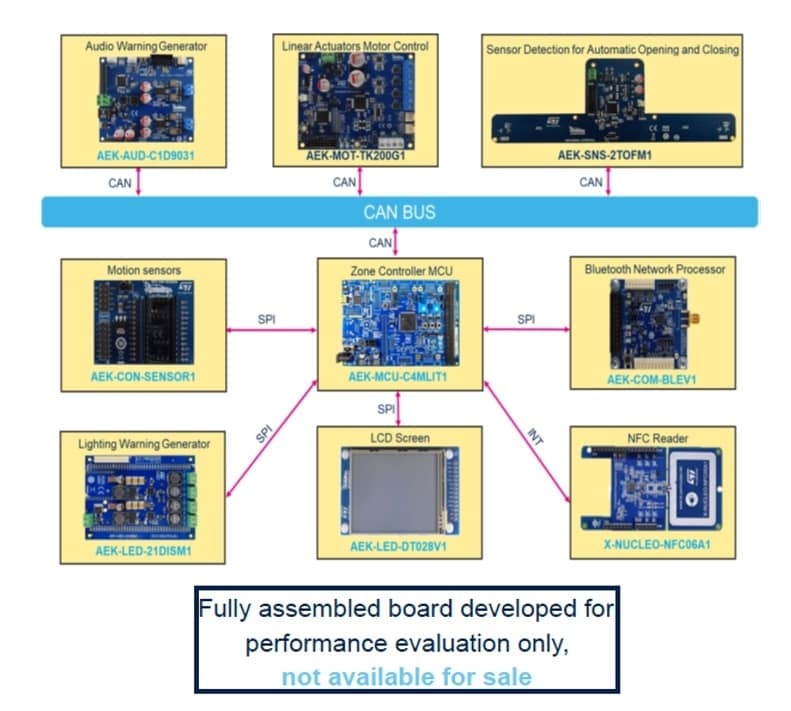

The AEKD-TRUNKL1 has been designed to address all these issues while increasing the system safety. Based on the newest zonal approach paradigm, this ST power liftgate system controls seven subsystems in parallel: acoustic and visual alerts, NFC and Bluetooth® Low Energy communication, motion and foot detection sensors, and linear actuator control. An LCD screen and a fail-safe button control are also available.

The first core function of the application is the precise control of the linear actuators that open and close the liftgate. This control has been developed with a model-based design. The code has been generated with MathWorks Embedded Coder. The model includes all the control and safety mechanisms for the actuation based on the dual feedback coming from the Hall sensors and from the current sense.

The second core function lies in the Time-of-Flight sensors placed under the bumper to recognize a specific foot movement designed to deliver a stable performance for the user and to avoid unwanted activations. Another great advantage is represented by the huge cost saving of the Time-of-Flight sensors compared to the normally used ones, like sonars.

The NFC tag in the mobile phone is a valid alternative to the sensor under the bumper because, even with hands full of bags, it is possible to approach the phone in the jacket pocket to the NFC reader placed in the power liftgate system.

A dedicated Android mobile phone app allows controlling the power liftgate system.

You can open the tailgate even few meters away before getting loaded of bags and packages. The app uses a token exchange with the power liftgate system to secure the communication and identification of the car owner. In addition, the car owner's app can temporarily o permanently elect other mobile phones running the same app as secondary phones having the car trunk access.

The motion safety subsystem is the last remaining block. It is based on a MEMS motion sensor to detect an eventual car motion during the liftgate actuations both at engine on and off. The detected motion stops the liftgate and generates an error.

The acoustic and visual alerts are activated at the beginning of all liftgate actuations and when a safety concern occurs (for example, the tailgate getting stuck by an obstacle).

For demo purposes, an LCD display has been added to illustrate the different states and errors of the power liftgate system. An external fail-safe button is also present to open or close the trunk.

The AEKD-TRUNKL1 is a fully assembled kit developed for performance evaluation only, not available for sale.

-

All features

- Control of two linear DC motor actuators to open and close the trunk

- Motion detection to prevent accidental trunk opening/closing

- Trunk locking and unlocking

- Visual alert through turning lights blinking at the beginning of the trunk opening/closing phase

- Acoustic alert through a beeper at the beginning of the trunk opening/closing phases

- Trunk opening/closing with an NFC tag key

- Trunk opening/closing via mobile phone app via Bluetooth® Low Energy

- Mini-infotainment touch display showing trunk state

- Self-calibration of the system motors

- Trunk opening/closing jam detection

- Trunk opening height adjustment

You might also like...

Featured Videos

All resources

| Resource title | Version | Latest update |

|---|

Bill of Materials (1)

| Resource title | Version | Latest update | |||

|---|---|---|---|---|---|

| 1.0 | 17 Jun 2022 | 17 Jun 2022 |

Schematic Pack (1)

| Resource title | Version | Latest update | |||

|---|---|---|---|---|---|

| 1.0 | 17 Jun 2022 | 17 Jun 2022 |

Quality and Reliability

| Part Number | Marketing Status | Package | Grade | RoHS Compliance Grade | WEEE Compliant | Longevity Commitment | Longevity Starting Date | Material Declaration** |

|---|---|---|---|---|---|---|---|---|

| AEKD-TRUNKL1 | NRND | CARD | Industrial | Ecopack2 | Yes | - | - | |

AEKD-TRUNKL1

Package:

CARDMaterial Declaration**:

(**) The Material Declaration forms available on st.com may be generic documents based on the most commonly used package within a package family. For this reason, they may not be 100% accurate for a specific device. Please contact our sales support for information on specific devices.

You’re now leaving st.com and will be re-directed to our Partner’s website.

For the latest innovations and solutions from ST, sign up for our newsletters.

Sample & Buy

| Part Number | Marketing Status | Budgetary Price (US$)*/Qty | Order from ST | Order from distributors | Package | Packing Type | RoHS | Country of Origin | ECCN (US) | ECCN (EU) | Supplier | Core Product | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AEKD-TRUNKL1 | | | distributors No availability of distributors reported, please contact our sales office |

|

|

AEKD-TRUNKL1 NRND

(*) Suggested Resale Price (USD) per defined quantity for BUDGETARY USE ONLY. For quotes, prices in local currency, please contact your local ST Sales Office or our Distributors